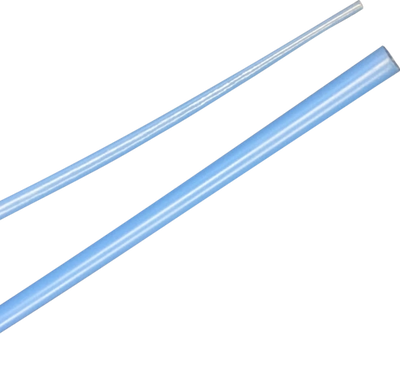

Taper / Bump tubing

Bump tubing, or taper tubing, are extrusions that vary in diameter through the length of the tubing. Typically, the proximal end of the bump tube (end closest to the device operator) is the larger of the two diameters, while the distal end is smaller.

Bumps tubes are great for combining devices where varying component diameters are necessary. Taper tubing makes connecting components simpler as they do not require additional processes or materials to join together devices.

Taper tubing in can be extruded in multi lumen configurations as well. This allows the easier insertions of instruments and drugs during minimally invasive procedures. Bump tubing can also be manufactured from a range of materials and in a variety of configurations. The length of the transition(s), and outside diameters, can also be customized as needed.

Bump / Taper Tubing; Proximal and Distal Ends

Materials

Pebax® Nylon HDPE LDPE TPU PVC PEEK FEP Polycarbonite PET

PLLA PLGA PLA PGA

Our extrusion experts at GenX possess the knowledge and equipment needed to ensure high quality, repeatable single lumen extrusions. Whether you need quick R&D runs, or high volume production quantities, GenX Medical can rapidly design and manufacture the proper tooling needed for your custom extrusion designs. Our internal capabilities allow precise, on-demand tooling to be manufactured for quick turnarounds or when critical adjustments are necessary.

GenX has acquired and developed specialized equipment and techniques necessary to extrude a variety of polymers, and maintain their original properties during the extrusion process. When materials require special considerations for moisture, filtration, or cooling, GenX applies resin-specific methods to ensure most stable and constant extrusion runs. With many medical grade polymers on hand, most single lumen extrusions can be manufactured within a week.

GenX Medical, LLC

4701 Wilson Rd, Bldg A, Chattanooga, TN 37410

As for me, I call to God, and the Lord saves me.

Psalm 55:16

GenX Medical © 2021 - All Rights Reserved.

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.